A Vision for a Better Way

Hyperlite Mountain Gear began with a relentless pursuit of a simple idea: that your gear should never get in the way of your adventure.

Founder, Mike St. Pierre, saw a gap between the heavy, over-engineered equipment the industry was offering and what was truly needed for a more efficient and enjoyable experience in the backcountry.

This vision for a better way—and the search for a material that could make it a reality—is what led him to Dyneema® fabrics and sparked a revolution in ultralight gear.

Engineered for the Backcountry

At the heart of our products is Dyneema®, a material that looks like a fabric but is scientifically closer to a high-tech, multi-layer laminate. It's famous for being stronger than steel at a fraction of the weight, and it's what allows us to create exceptionally light, durable, and weatherproof gear. We use it in a few key variations:

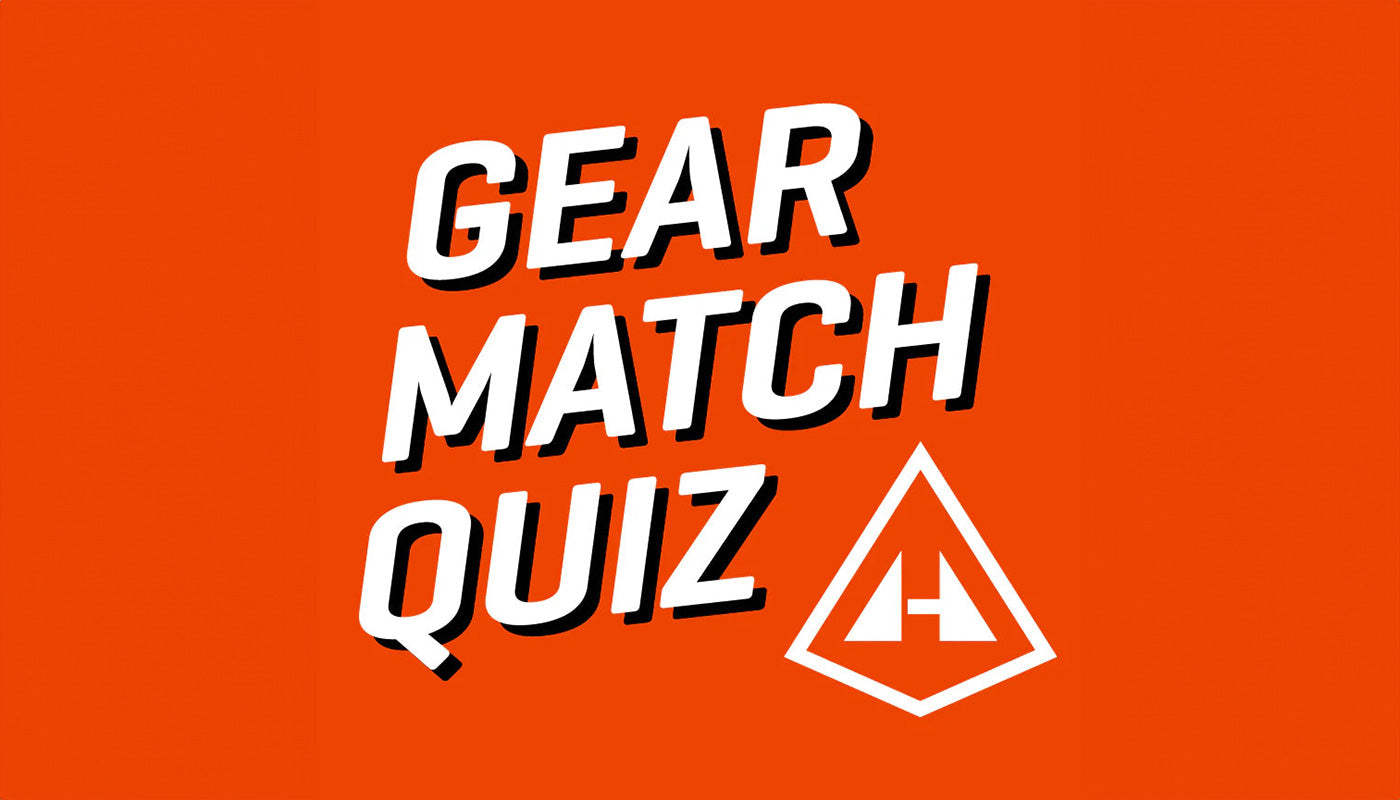

Dyneema® Woven Composites

The next evolution. This is our most advanced pack material, created in partnership with Dyneema®. By harnessing the power of the world’s strongest fiber™ in both the woven face fabric and the internal filament core, Dyneema® created a material with unmatched durability and tear resistance, which we are proud to be the first to bring to market.

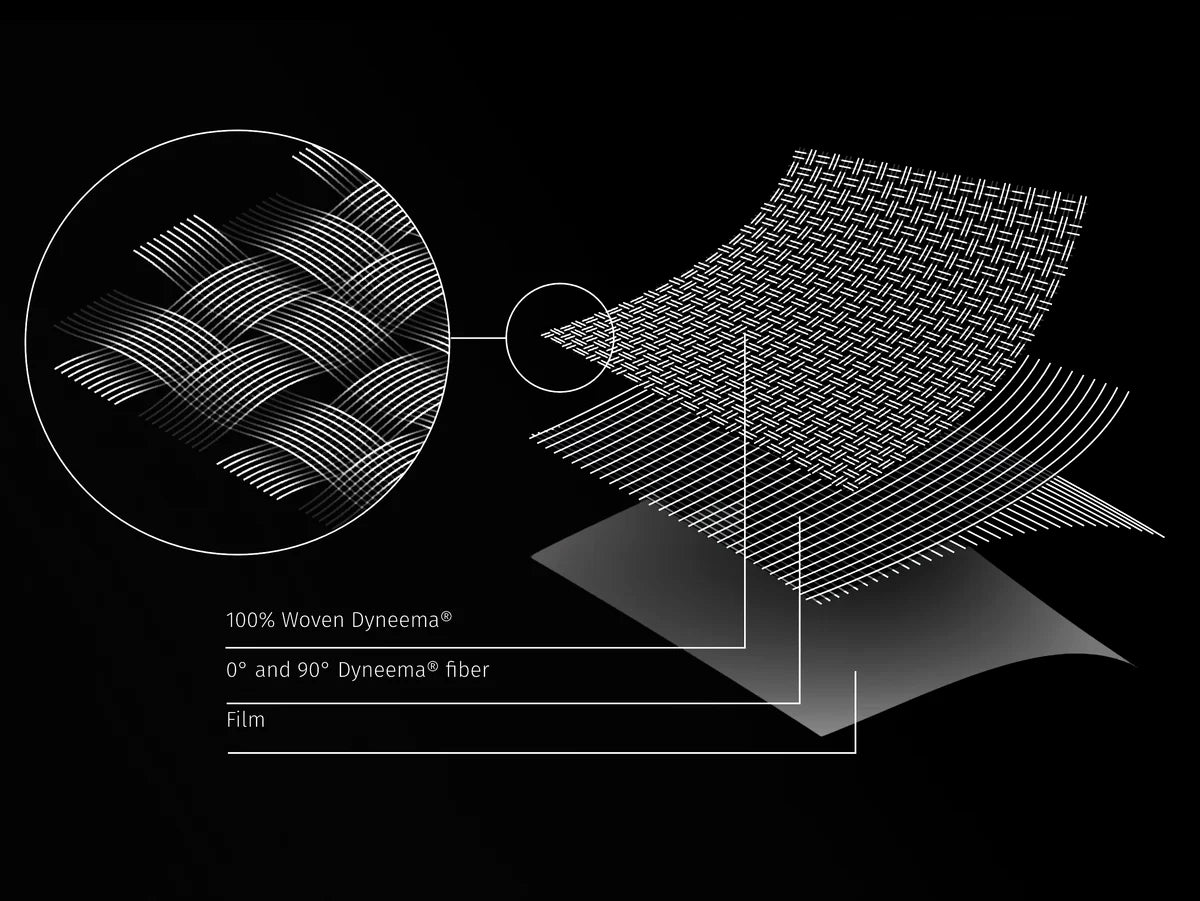

Dyneema® Composite Hybrids

The workhorse of our packs. For added durability and abrasion resistance, the Dyneema® Composite Fabric core is laminated to a woven face fabric (like polyester or woven Dyneema®). This hybrid approach creates an ultralight material that can withstand the incredible abuse of high-mileage trips through abrasive environments.

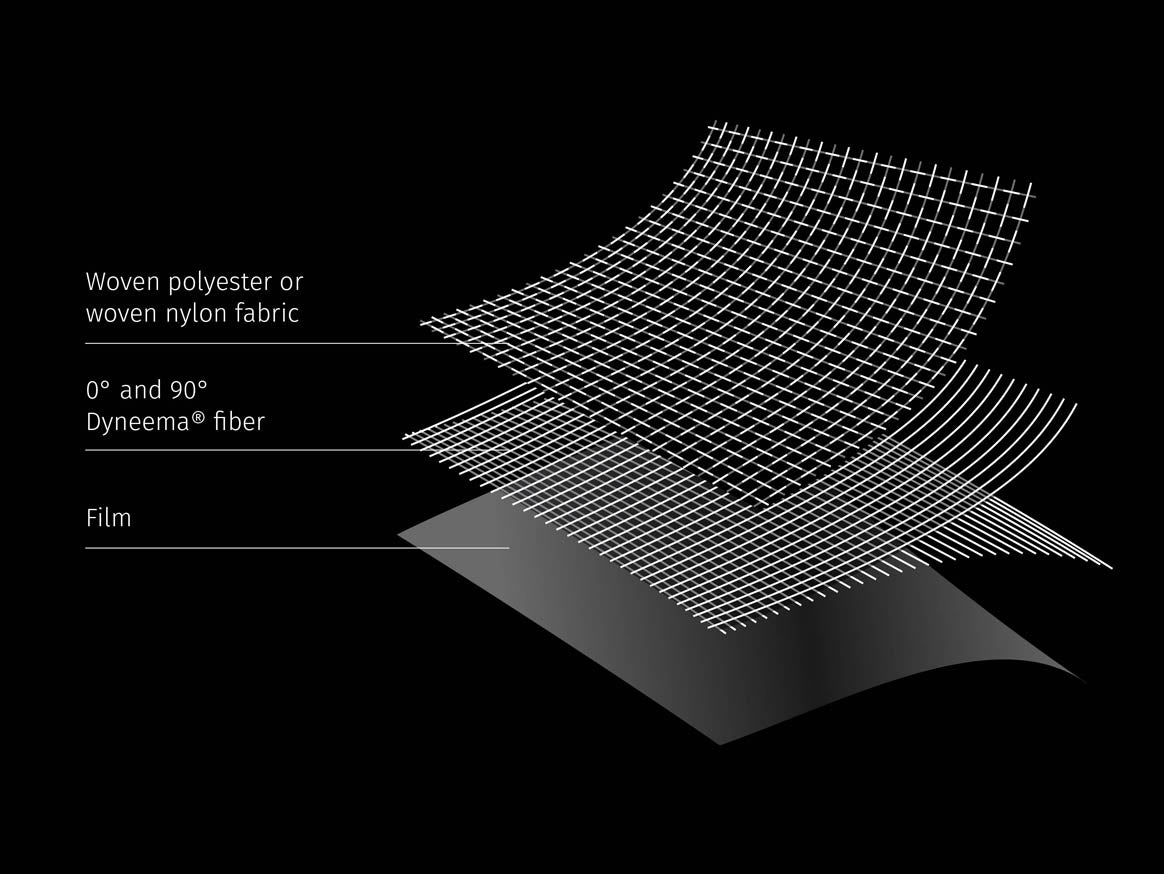

Dyneema® Composite Fabrics

At the heart of our products is Dyneema®, a material that looks like a fabric but is scientifically closer to a high-tech, multi-layer laminate. It's famous for being stronger than steel at a fraction of the weight, and it's what allows us to create exceptionally light, durable, and weatherproof gear. We use it in a few key variations.

Explore the Innovation

Dyneema® Fabrics are a feat of material science. For a complete technical breakdown of this fabric, including all the specs and testing data, read the full story on our blog.

Our Special Sauce: The Dyneema® Advantage

We build our gear around Dyneema® composite, a technology so advanced it’s trusted in aerospace, armor, and sailing applications. Leveraging the performance benefits of the world's strongest fiber™ these materials allow us to engineer products that are radically different.

Impossibly Light

Dyneema® fiber has a strength-to-weight ratio 15x greater than steel. This lets us build packs that weigh a fraction of the competition, so you can go farther, faster, and with less strain on your body.

Inherently Waterproof

Dyneema® composites are 100% waterproof on their own—no coating to wear out, no rain cover needed. We fully tape our seams to create a weatherproof shell that protects your gear through downpours and river crossings. Period.

Incredibly Durable

Engineered for the most demanding conditions, the new Woven Dyneema® Composite offers 10x more abrasion resistance and 5x better tear resistance than our previous fabrics. It's built for relentless abuse.

Built to Endure: Our Testing Standard

A pack that fails in the field is more than an inconvenience; it's a liability. That's why every material we use is subjected to a battery of punishing tests before it ever makes it into a product. We pull it, puncture it, grind it, and expose it to extreme conditions to simulate years of hard use. We don't just meet industry standards; we aim to set them. This ensures the gear you trust with your safety is worthy of that trust.

Confidence When It Counts

Dyneema® Naming Update

Here is a helpful translation key for the Dyneema® fabrics used across our product lines:

| Old Name | New Name |

|---|---|

| DCH50 | Dyneema® Composite Hybrid 3.8 |

| DCH150 | Dyneema® Composite Hybrid 5.1/5.9 |

| 400D Fully Woven | Dyneema® Woven Composite 5.0 |

| DCF6 | Dyneema® Composite Fabric 0.55 |

| DCF8 | Dyneema® Composite Fabric 0.75 |

| DCF10 | Dyneema® Composite Fabric 0.96 |

| DCF11 | Dyneema® Composite Fabric 1.3 |

Note: The new Dyneema® Woven Composite 3.9 featured in our core packs is a brand-new material and does not have a direct predecessor.

Your Next Adventure is Waiting.

Ready to feel the difference? Explore our collections and find the perfect lightweight, waterproof, and durable gear for your next journey.